What are PHP© cold stamping wires?

PHP© phosphated wires are those to which sodium soap has been applied at very high pressure during the finishing process. This innovative system radically improves their performances, due to the very low friction coefficients obtained.

The advantages of PHP wires

Improved wire deformation performance.

Allows the manufacture of highly complex parts.

Offers coating values of more than 80%.

Increases machine life by minimising die consumption.

Which processes are supported by this new SEBIR product?

The supported processes are all those that include a finishing drawing (skin-pass):

SUPPORTED GRADES

This process is applicable to all wire qualities manufactured by SEBIR.

SUPPORTED DIAMETERS

The range goes from diameter 1.80 to diameter 40 mm.

How does it work? The theoretical principles of PHP©

The random roughness generated by the phosphate coating of a wire has a ratio between the “Visible Developed Surface Area” and the “Actual Developed Surface Area”: SDR/SDA > 20. This ratio is very favourable if we are able to cover this surface with the right lubricant.

The PHP© process applies the lubricant (sodium soap) at very high pressure, which makes its coverage reach values of over 80%, compared to 42% and 48% for conventional technology.

The extra reserve of lubricant is used at each stage of the deformation process according to the needs of the deformation process. The application of sodium stearate on the layer of zinc phosphate crystals at “very high pressure” allows closer contact between (PO4)2Zn3 crystals and the sodium soap, which reacts with the phosphate to give a homogeneous and continuous layer of zinc stearate (excellent lubricant). This completely covers each of the crystals that form the phosphate coating.

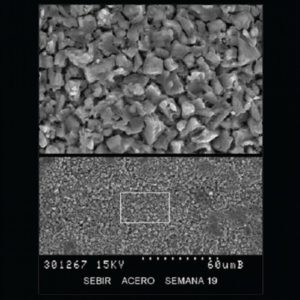

SEM image of the steel surface after the PHP© drawing process.

SEM image of the surface of the phosphated steel before the application of the lubricant.

The benefits of using SEBIR PHP© wires

- REDUCED FRICTION COEFFICIENT

With this technology, a friction coefficient of μ=0.04 is obtained at the beginning of the deformation. After the most complex deformations, this friction coefficient remains at very low values of μ=0.12, compared to wires with conventional technology (μ=0.40).

- MANUFACTURE OF VERY COMPLEX PARTS

PHP© wires allow the manufacture of highly complex parts, which cannot be manufactured even with wires using the Phosphate-Polymer process.

- INCREASES THE MACHINE LIFETIME AND REDUCES COSTS

This product increases the life of deformation tools, due to lower working temperatures and lower loads on the tools as a result of the low friction coefficients.

- CUSTOMER-SPECIFIC ROUGHNESSES

PHP©/LR (low roughness) wires allow the production of wires with customer-specific roughness. Depending on the lubricant used, roughnesses of up to Ra <= 0.22 can be achieved. This detail makes it possible to obtain parts with surface finishes equivalent to grinding, thus saving costly machining operations.

Any questions? Our team will advise you

If you want to know more about PHP© wires, just contact us. We will offer you the best advice to guarantee solutions that fit your needs.